LVDT Sensors - 7 Key Advantages of Linear Variable Differential TransformerTechnology by Kavlico

1. Executive Summary

LVDT (Linear Variable Differential Transformer) sensors are the gold standard in non-contact linear position measurement, delivering unparalleled precision, reliability, and frictionless performance. With rugged construction and virtually unlimited operational lifespan, LVDTs are critical components in aerospace, industrial automation, energy systems, and scientific research, where accuracy and reliability are non-negotiable.

This article provides a comprehensive, in-depth engineering-level explanation of LVDT technology, with a dedicated focus on Kavlico LVDTs (a globally trusted brand under Sensata Technologies), and the reason behind sourcing them through Inventechs Technology, the authorized distributor for the GCC and MENA regions, to ensure customers benefit from genuine Kavlico solutions with guaranteed performance, reliable availability, expert technical guidance, and full after-sales support.

Table of Contents

2. What is LVDT Sensor?

LVDT is an electromechanical transducer that converts a core’s linear displacement (mechanical movement) into an electrical signal without mechanical contact, using transformer principles.

Unlike resistive sensors, an LVDT operates friction-free, eliminating wear, minimizing hysteresis, and ensuring absolute position referencing even after power loss.

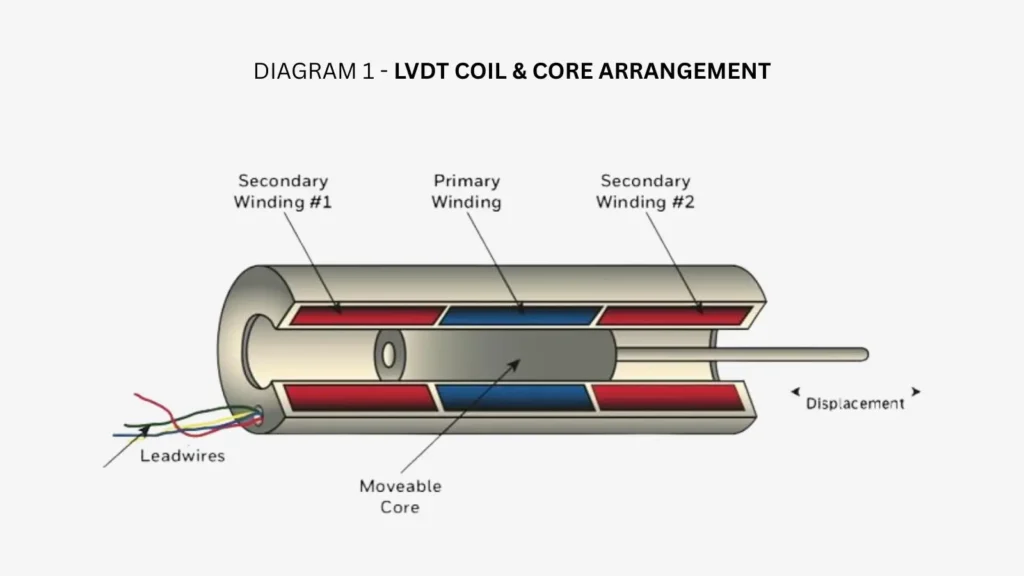

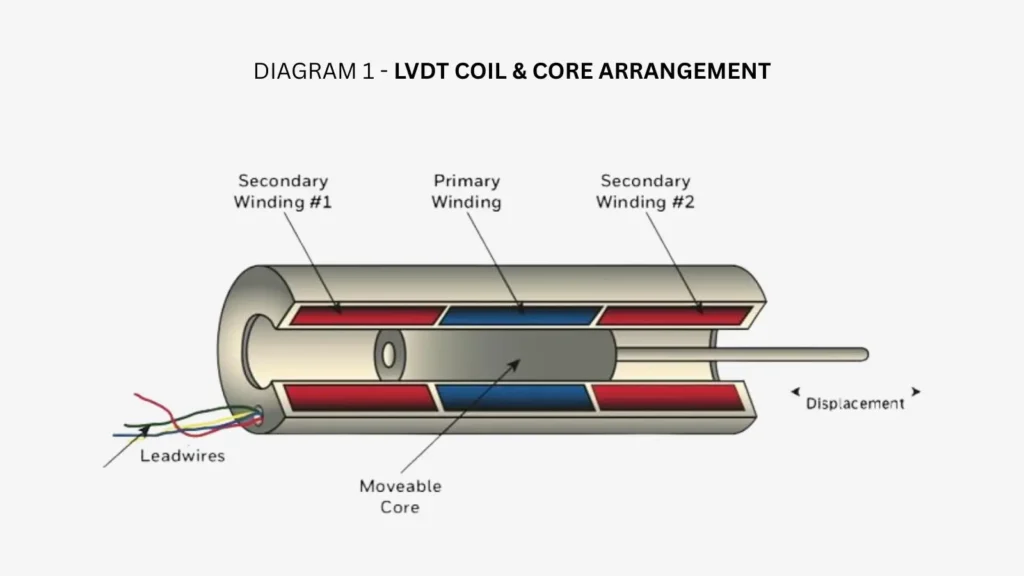

The working concept is based on mutual inductance variation:

- A central primary coil is energized by AC.

- Two secondary coils are placed symmetrically on either side of the primary, wound in series opposition (opposite polarity)..

- A movable soft iron (ferromagnetic) core, attached to the object being measured, slides inside the coils without contact, altering the magnetic coupling between the primary and each secondary

Displacement changes the induced voltages in the secondaries, and the differential output directly corresponds to position, while phase polarity indicates direction

3. Internal Construction and Materials Engineering

Kavlico LVDTs are designed for mission-critical environments:

- Primary Winding: High-purity copper with controlled turn count for minimal resistance and stable inductance under temperature extremes.

- Secondary Windings: Matched coils for perfect signal symmetry, minimizing linearity error.

- Ferromagnetic Core: Nickel-iron alloy with ultra-low coercivity to reduce magnetic lag.

- Bore Liner: Non-magnetic sleeve ensuring smooth core movement without contact.

- Housing: Stainless steel or nickel-plated metal, providing EMI shielding and corrosion resistance.

- Encapsulation: High-temperature epoxy or resin to protect windings from vibration, moisture, and thermal shock.

This robust build ensures operational integrity from −55 °C to +200 °C, withstanding high-G vibrations, shock loads, and chemical exposure, while meeting MIL-STD and RTCA-DO-160 compliance requirements

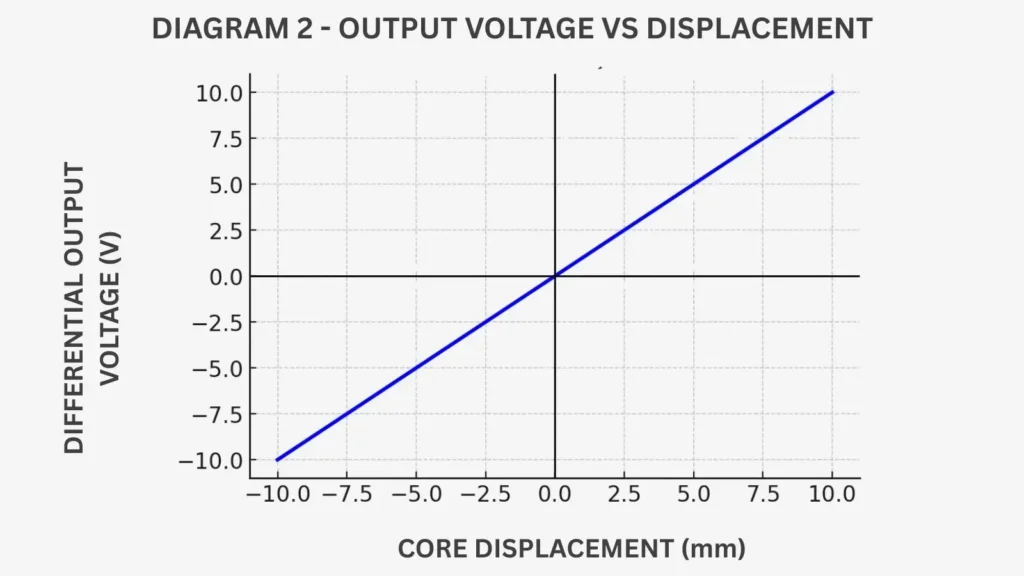

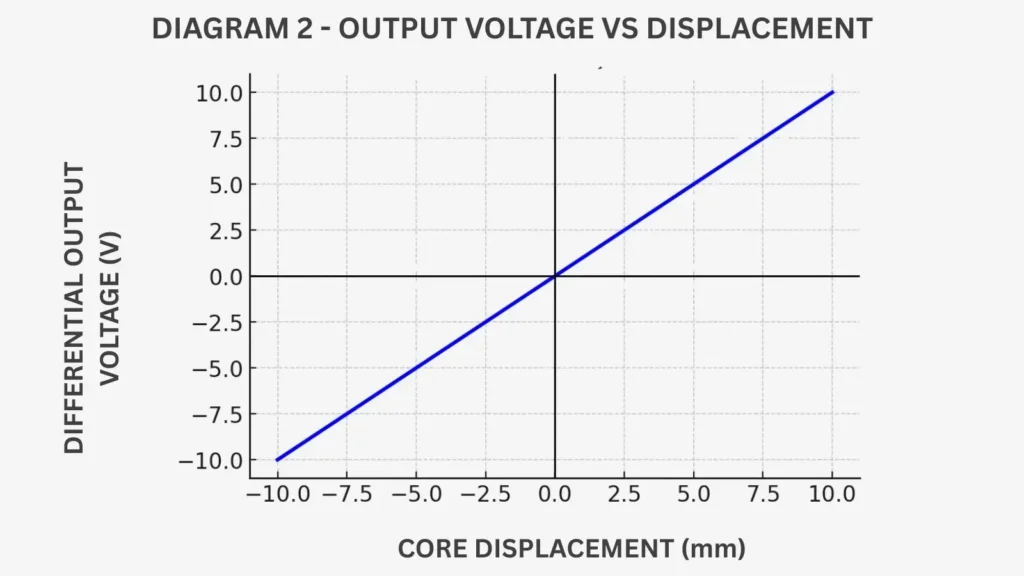

4. Electromagnetic Operating Principle

When the core is centered (null position), induced voltages in the secondary coils are equal and opposite, canceling out to yield zero output.

When the core shifts:

- Moving toward Secondary A: increases coupling there while reducing coupling to Secondary B, resulting in a positive-phase voltage.

- Moving toward Secondary B: reverses the phase.

The output signal is linear proportional to displacement within the sensor’s linear range.

5. Core Technical Advantages and Performance Metrics

Kavlico LVDTs excel in:

- Infinite Resolution: The non-contacting induction design enables sub-micron output, limited only by electronics.

- Friction-free (No Wear Mechanism): No sliding parts; ideal for long-term reliability.

- Environmental Resilience: Operates under extreme temperatures, radiation, and vibration.

- Absolute Measurement: Returns to exact reference upon power-up without recalibration.

- Ultra-low Hysteresis (<0.01% FS): Ensures repeatability in precision systems.

- High Linearity: Typically ±0.25% or better over full range.

EDP sensors precisely track rotor angle, ensuring optimal timing for coil activation and maximizing efficiency.

Looking for aSolution?

Our Technical Experts are Here to Bring your VISION to Life. Let’s DISCUSS How Our SOLUTIONS Can Maximize the VALUE of your PROJECT

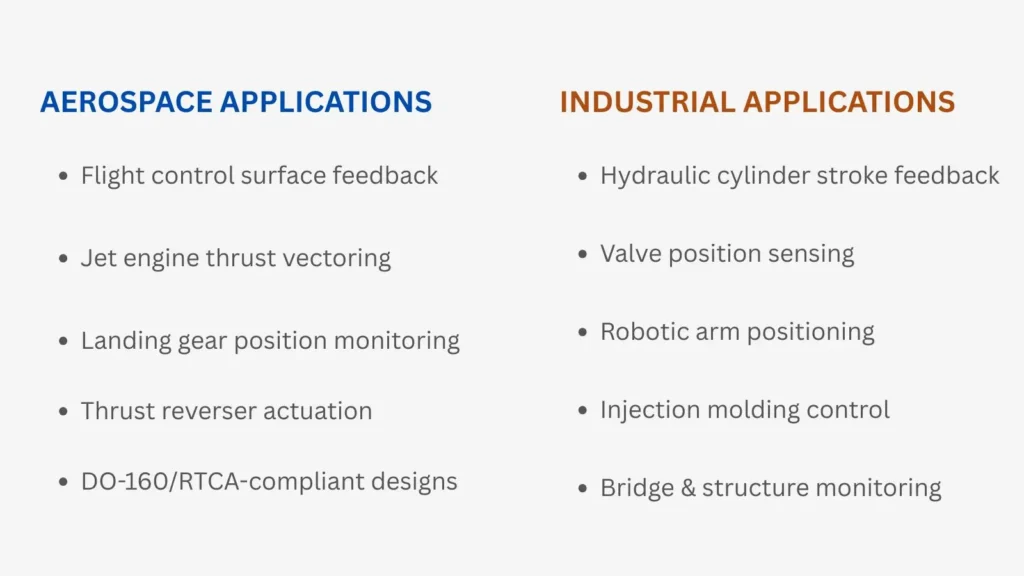

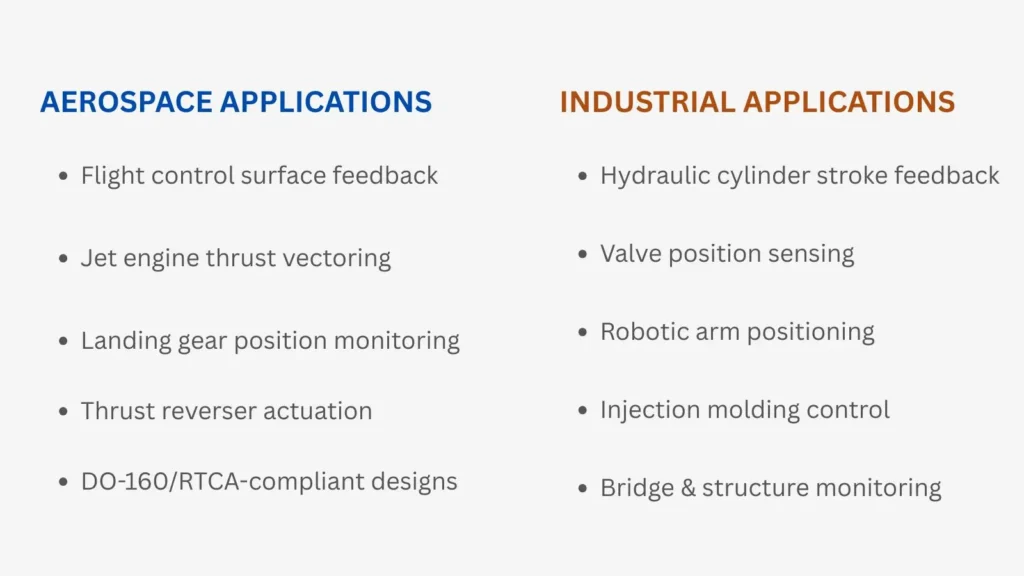

6. Versatile Application Sectors

- Aerospace: engine feedback, thrust reverser position, flight control.

- Industrial automation: robotics, hydraulic cylinders, valve control.

- Energy: Turbine blade pitch control, nuclear rod monitoring, Valve position monitoring in Oil & Gas Systems.

- Automotive: Suspension measurement, crash test rigs, Throttle / Pedal Position Measurement.

- Civil engineering: Structural displacement monitoring in bridges and dams.

7. Kavlico's Aerospace Integration

- DO-160 & RTCA Compliant Designs: Meeting stringent aerospace qualification.

- Redundant Channels: Dual/triple redundancy for continuous operation during partial failure.

- Temperature Compensation: Ensures accuracy across varying altitudes and environmental conditions (−55 °C to +200 °C).

- Hermetically Sealed Housings: Prevent contamination at high altitude.

8. Kavlico's Industrial Deployment

- Compatible seamless PLC/DCS integration.

- Housing resistant to oils, chemicals, and shock.

- Custom stroke measurement ranges from sub-millimeter to over 500 mm.

- Highly reliable feedback for automated systems and quality control.

9. Inventechs After-Sales and Lifecycle Support

As Sensata/Kavlico’s authorized distributor, Inventechs provides:

- Local stock availability: Minimizing lead time for urgent projects. (link to web)

- After-sales support and repair services:

• Minor repairs: ~10 days for single channel, ~15 days for multi-channel.

• Major repairs: ~15 days for single channel, ~21 days for multi-channel. - Certified calibration Services: Manufacturer-approved test and verification.

- Technical Consulting: Application engineering consultancies for integration and troubleshooting.

10. Why Kavlico LVDTs Outperform Competitors?

When selecting Linear Variable Differential Transformers (LVDTs) for mission-critical applications, performance and reliability specifications vary significantly across manufacturers. Kavlico has established industry leadership in delivering superior reliability, environmental durability, and measurement precision. The following key differentiators demonstrate the key advantages:

- Aerospace-Grade Qualification Across All Models: Unlike many competitors, all Kavlico designs meet aerospace standards.

- Multi-Channel Redundancy as Standard: Dual/triple redundancy ensures no single point of failure.

- Extended Temperature Range and Stability: Maintains accuracy from −55 °C to +200 °C.

- Superior Environmental Sealing: Hermetically sealed variants resist harsh conditions.

- Ultra-Low Hysteresis and High Linearity: Better than industry averages.

- Proven MTBF: Often exceeding 1,000,000 operational hours.

- Seamless Integration Support: Localized service and stock from Inventechs.

11. Strategic Conclusion

Kavlico LVDTs represent the pinnacle of displacement sensing technology, combining frictionless operation, aerospace-grade reliability, and industrial ruggedness. Through Inventechs Technology, customers gain the additional advantage of immediate availability, regional support, and factory-authorized repairs.

For mission-critical aerospace or industrial applications in the GCC and MENA, the combination of Kavlico technology and Inventechs’ local expertise is the optimal choice.

12. References

- Sensata Technologies.

- Kavlico Aerospace LVDT Datasheets.

- RTCA DO-160 Environmental Conditions Standard.

- Electromagnetic Theory for Transformer-Type Transducers.

- Inventechs Kavlico Page

Need Deeper Technical Specs? Contact our Engineering Team