Top 7 Benefits of Electric Drive Position SensorsAerospace Electrification

1. Introduction: A Game-Changer in Aerospace Electrification

The aerospace and defense industries are undergoing a radical transformation with the rise of Urban Air Mobility (UAM), Advanced Air Mobility (AAM), and Electric Vertical Takeoff and Landing (eVTOL) aircraft. These next-generation Electric Vehicles (EVs) demand high-efficiency, lightweight, and reliable components to ensure performance and safety.

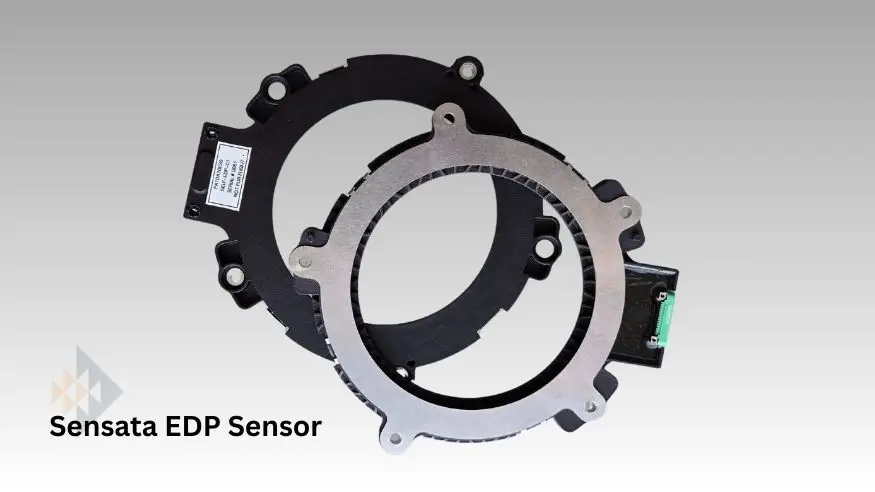

One critical component enabling this shift is the Electric Drive Position (EDP) Sensor, which ensures precise motor control in electric propulsion systems. In this blog, we explore Sensata’s EDP sensors, the role in axial flux e-motors, and why they are vital for the future of Electric Aviation.

Table of Contents

2. What is an Electric Drive Position (EDP) Sensor?

An Electric Drive Position (EDP) Sensor is a high-precision device that measures the rotational or linear position of an electric motor’s rotor relative to its stator. This feedback is crucial for efficient motor commutation, torque control, and system reliability.

Key Components of EDP Sensor:

- Sinusoidal traces on a PCB: Detects rotor position via eddy currents.

- Thin conductive target (steel/aluminum): Attached to the rotor, interacts with sensor coils.

- Encapsulated housing: Protects against environmental factors (dust, humidity, vibration).

- Integrated signal processing: Eliminates the need for external electronics, reducing weight and complexity.

Unlike traditional resolvers, Sensata’s EDP sensors are contactless, magnet-free, and offer superior accuracy (±1° electrical error) while maintaining a low profile and lightweight design.

3. What is an E-Motor in Aerospace Applications?

Electric motors (e-motors) are replacing traditional combustion engines in UAM, AAM, and eVTOL aircraft due to their higher efficiency, lower emissions, and reduced maintenance.

Types of E-Motors in Aerospace Industry:

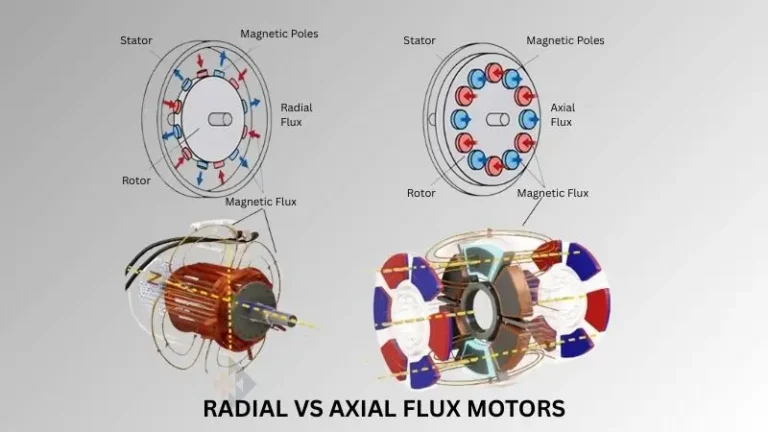

Radial Flux Motors: Traditional design with magnetic flux perpendicular to the axis.

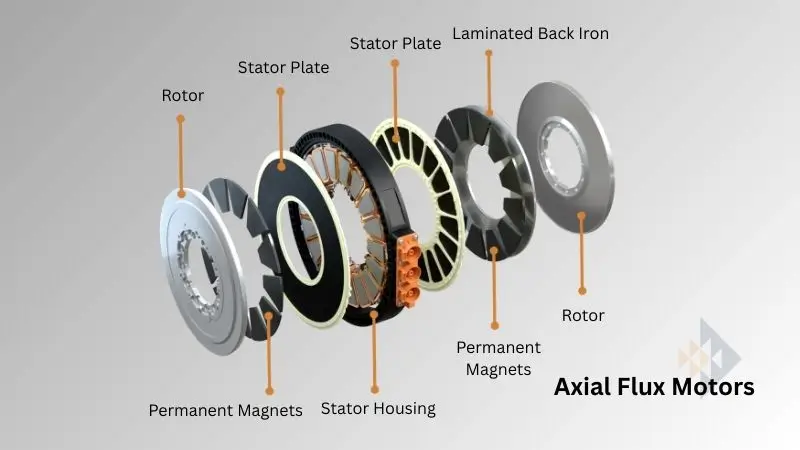

Axial Flux Motors: Advanced design with flux parallel to the axis, offering higher power density and compactness.

Axial flux motors (also called pancake motors) are increasingly preferred in aerospace due to their lightweight, low-profile, and high-torque capabilities, making them ideal for electric propulsion systems.

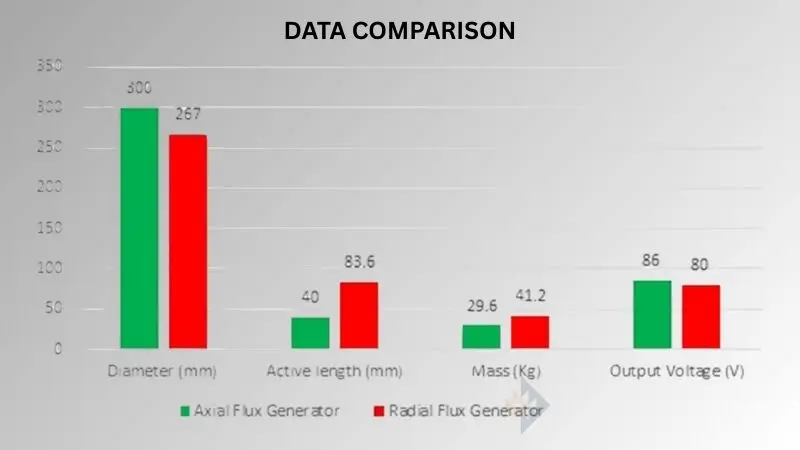

4. Technical Difference Between Radial and Axial Flux E-Motors

| Feature | Radial Flux Motor | Axial Flux Motor |

|---|---|---|

| Flux Direction | Perpendicular to axis | Parallel to axis |

| Material Used | Non-grain-oriented steel (NGOES) | Grain-oriented steel (GOES) |

| Efficiency | Lower (higher iron losses) | Higher (reduced losses) |

| Size & Weight | Longer, heavier | Compact, lightweight |

| Power Density | Moderate | High |

| Typical Use Case | Conventional EVs | Aerospace, high-performance EVs |

Axial flux motors provide better efficiency, lower weight, and higher power density, making them ideal for electric aircraft.

5. How Does an Axial Flux E-Motor Work?

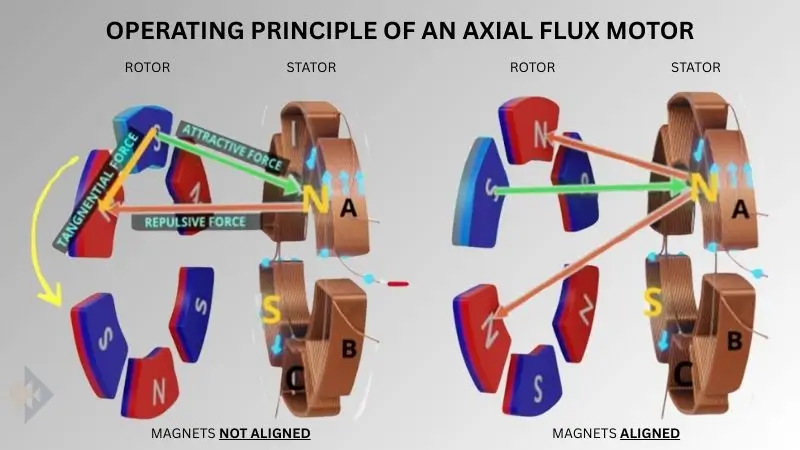

1. Magnetic Interaction:

- The rotor has permanent magnets, while the stator has electromagnet coils.

- When coil A is energized, it attracts the rotor’s opposite pole, creating torque.

2. Commutation

- As the rotor aligns with coil A, coil B is energized, maintaining continuous rotation.

3. Position Sensing:

EDP sensors precisely track rotor angle, ensuring optimal timing for coil activation and maximizing efficiency.

Why is Position Sensing Critical?

- Prevents motor stalling or misalignment.

- Ensures smooth torque delivery for stable flight.

6. Advantages of Using Axial Flux E-Motors

✔ Higher Efficiency: Reduced iron losses due to GOES material.

✔ Lightweight & Compact: Ideal for space-constrained aircraft.

✔ High Torque Density: Better performance in takeoff and climb phases.

✔ Scalability: Easily adapted for different motor sizes.

7. Sensata Aerospace EDP Sensors: The Ultimate Position Sensing Solution

Sensata’s EDP sensors outperform traditional resolvers with:

✅ Superior Accuracy (±1° electrical error).

✅ Redundant Dual-Channel Design: Enhances safety.

✅ Integrated Signal Processing: No need for heavy external electronics.

✅ Immune to Magnetic Interference: No shielding required.

✅ Robust Design: Resistant to vibration, dust, humidity, and oil.

Comparison: EDP Sensor vs. Resolver

| Parameter | EDP Sensor | Resolver |

|---|---|---|

| Profile | Low | High |

| Weight | Light | Heavy |

| Signal Processing | Integrated | External |

| Accuracy | ±1° | ±2-5° |

| Magnetic Immunity | Yes | No (requires shielding) |

8. Why is the Electric Drive Position Sensor Important in Aircraft Applications?

Electric Drive Position Sensors (EDP sensors) play a mission-critical role in modern aircraft, particularly in electric and hybrid-electric propulsion systems. Their importance stems from the need for precision, reliability, and safety in aviation. Here’s why they are indispensable:

1. Ensures Precise Motor Control for Flight Stability

- Aircraft control surfaces (flaps, ailerons, rudders) and electric propulsion systems require exact positioning to maintain stability.

- EDP sensors provide real-time rotor position feedback, ensuring motors deliver the correct torque and speed for smooth operation.

- Without accurate sensing, misalignment or delays in motor response could lead to unstable flight conditions.

2. Enables Efficient Power Management

- Electric aircraft rely on battery power, making energy efficiency crucial.

- EDP sensors optimize motor commutation timing, reducing energy waste and extending flight range.

- In axial flux motors, precise position sensing maximizes torque output while minimizing losses.

3. Supports Redundancy and Fault Detection

- Aviation systems demand fail-safe operation.

- Sensata’s EDP sensors feature dual-channel redundancy, allowing cross-verification of position data.

- If one sensor fails, the backup ensures continuous operation, preventing catastrophic failures.

4. Enhances Safety in Fly-by-Wire Systems

- Modern aircraft use fly-by-wire (FBW) systems, where electronic signals replace mechanical linkages.

- EDP sensors provide closed-loop feedback to flight computers, ensuring actuators move as commanded.

- Any sensor drift or failure can trigger automatic corrective actions or pilot alerts.

5. Reduces Weight and Simplifies Systems

- Traditional resolvers are bulky and require external signal processing.

- Sensata’s EDP sensors are lightweight, compact, and integrate signal conditioning, reducing overall system weight—a critical factor in aviation.

6. Withstands Harsh Aerospace Environments

- Aircraft face extreme vibrations, temperature shifts, and contaminants (dust, oil, humidity).

- EDP sensors are designed to resist these conditions, ensuring long-term reliability without performance degradation.

7. Critical for Autonomous and eVTOL Operations

- eVTOL and drone** aircraft depend on electric propulsion for vertical lift and transition to forward flight.

- Precise motor control is vital to prevent oscillations, instability, or crashes.

- EDP sensors enable smooth transitions between flight modes, ensuring passenger safety.

Looking for aSolution?

Our Technical Experts are Here to Bring your VISION to Life. Let’s DISCUSS How Our SOLUTIONS Can Maximize the VALUE of your PROJECT

9. Sensata EDP Sensors Applications in Aerospace, Defense, and Aircraft

- eVTOL & UAM Aircraft: Precise motor control for electric propulsion.

- Military Drones: High-reliability sensing for unmanned systems.

- More Electric Aircraft (MEA): Replacing hydraulic actuators with electric drives.

- Spacecraft & Satellites: Lightweight, high-efficiency motors for space applications.

10. Conclusion

Without high-accuracy position sensing, electric aircraft would struggle with efficiency, safety, and performance. The shift toward electric aviation demands innovative, efficient, and reliable components. Sensata’s Electric Drive Position (EDP) Sensors provide the precision, durability, and compactness needed for axial flux e-motors in the future of UAM, AAM, eVTOL, and military electric aircraft.

By enabling higher efficiency, reduced weight, and superior control, these sensors are paving the way for the future of electric flight. Sensata’s EDP sensors dominate in aerospace due to:

- Unmatched reliability in harsh conditions

- Lower SWaP (Size, Weight, and Power)

- Reduced lifecycle costs

- Intrinsic safety (no single-point failures)

For next-gen aircraft where failure is not an option, EDP sensors provide the optimal blend of precision and ruggedness.

11. References

- Sensata Technologies. (2023). Electric Drive Position Sensing for UAM/AAM/eVTOL Applications.

- Industry reports on axial flux motors and electric aviation trends.

Need Deeper Technical Specs? Contact our Engineering Team